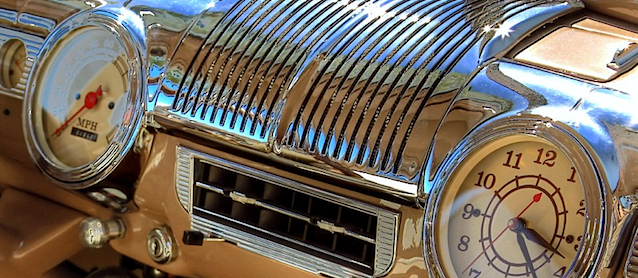

Leather and chrome have adorned car interiors for nearly a century. For good reason too – the combination looks great. In recent years, however, automakers looking to cut costs have swapped chrome accents with bland plastic substitutes. Remember when the dials on car radios were chrome? Now they’re plain black. What a shame!

If you’re working on an interior that you’d like to spruce up with chrome, you’re in luck. Advancements in technology allow for nearly any material’s surface – including plastic – to be chromed. Below are six ways you can transform interior plastics to chrome. Some you’ll need to hire a professional to do, while others you can do yourself.

Services You Have to Send Parts Out For

1. Plastic chrome plating

The process of chrome-plating plastic is similar to that of metal. The surface of the plastic piece is coated in copper and nickel before chrome is applied. Because flexible plastics are susceptible to stress fractures, this process is only suitable for rigid plastics. For more information, check out Paul’s Chrome Plating in Evans City, PA.

2. Vacuum Metalizing

The vacuum method, which is commonly used to make flashlight reflectors, is another great option. Here, plastic parts are washed and given a basecoat before exposed to an aluminum vapor cloud. When the vapor cloud comes in contact with the piece to be coated, it bonds to its surface leaving a chrome-like shine. Companies like Mueller Corporation in East Bridgewater, MA specialize in vacuum metalizing.

3. Spray Chrome

Allowing for virtually any surface to be chromed, this three-layer, water-based process is one of the most exciting breakthroughs in chrome plating. Parts are prepped and sprayed with a black base coat, then coated with a nontoxic chrome formula that applies so smoothly it doesn’t run. Lastly, the parts are cleaned with water and clear coated. This video by Jay Leno’s Garage shows you just how it’s done: Spray-On Chrome.

Chroming You Can Do On Your Own

4. Stretch Chrome Film

Stretch chrome is the latest product in an exciting new line of car-wrap films offered by Alsa Corp. The adhesive backed film stretches in every direction, allowing for curved surfaces to be easily wrapped. Best of all, it’s affordable. Stretch chrome retails for $5.99 per square foot.

5. Killer Chrome

Probably the best solution for trim shops, Killer Chrome is a three-step painting process similar to Spray Chrome, but can be done in your own garage with a $129 kit from Alsa Corp. Don’t confuse Killer Chrome for the cheap spray cans of the past that advertised a chrome finish, but delivered silver paint. Killer Chrome is the real deal.

6. Mirror Chrome FX Sheeting

Similar to Stretch Chrome, FX sheeting is a peel and stick laminate. However, this product is only intended for flat surfaces – as it does not have any stretch capabilities. The stunning mirror-chrome finish is great for accent pieces on dashboards, custom consoles and finished trunks. Before you spend $14 per square foot, try Alsa Corp‘s sample pack – which includes mirror chrome, as well as 11 other finishes like brushed aluminum and burl wood.

OK, so in reality you’re not actually transforming plastic into chrome. Rather, you’re giving cheap-looking parts a higher-end chrome finish. Sometimes that’s good too. These options are to real chrome what gold plating is to alchemy – a feasible and attractive alternative.

The stretch film Alsa Corp. is producing is ridiculously insane! Cant wait to try It out.

Agreed. It’s awesome!

I ordered and paid for a kit from Alsa, but never received it. After multiple calls and emails to them. They refuse to even respond. Beware this company

They have never responded to any attempts of communication with me and I’ve never even ordered anything from them. It’s a shame because they have so many cool products but I will not take a chance with a company like that.

Hi I’m in Perth wa were can I get a chrome kit for plastic,thanks for your help Dee.

I just want to setup a new chorme plant can u send me the details for setup the plant

Contact 9215301515

i am new

For true OEM Chrome plating, parts should be electroplated. There are not many companies that will take individual parts. Paul’s Chrome will work with individual parts. Companies like Romac Products will do the molding and chrome plating of parts. Either way it’s an expensive process.

Here are the sites I mentioned

http://www.paulschrome.com

http://www.romacproducts.com

All the best

hydro chrome vs killer chrome?

https://www.youtube.com/watch?v=yvtRYZ5EasA

http://www.alsacorp.com/live/view_killerchrome_demo.html

Does anyone have experience with both systems?

If yes, which one is better and why?

Looks like both are sold at Home Depot online

I just saw the “Killer Chrome” in person at their offices in Los Angeles. The video is very misleading. Once you put the clear coat on, it looks like crappy rustoleum “chrome”. No better for 30 times the cost. Don’t waste your money.

Hello, after reading this remarkable article i am also cheerful to share my knowledge here with mates.

Feel free to surf to my web site – Professional House Painters

Hi Sir/mam, I am in Kenya and set up a new product so I need this plastic chrome and the complete mothered how it is done.

were can I buy the row products.

Thanks.

My question is when using the killer chrome, in doing it yourself do you have to worry about it cracking later on down the line?

Where can I purchase my own plastic chrome kit

Hi mate, I’ve been looking into this chroming system for some time now, and I’m still very interested in starting up my own business. Is there a franchise that people can buy into or not. Cheers mick.

Out of curiosity, let’s say I had a re-manufactured plastic part made by a 3D printing process. White there is a polishing process in 3D printing, some “grain” effects still result because of pixelation.

My question is, besides the spray on chrome finishes (which may “puddle” in small cavities, effectively filling them in), which chrome process would have the best chance of obscuring such “grain.”

Also, do any of the plastic chromed pieces FEEL like genuine chrome or do they warm to the touch easily (as plastic usually does)?

All surfaces need to be prepared so that there is a completely smooth, just like a cars painting surface. It needs to be sanded down, starting with a semi-coarse down eventually to a very, very fine paper, then cleaned of all particles. Otherwise all of the flaws will be seen in the end result.

FEEL? The temperature of the piece you are feeling is not from the chrome plating, it is from the material you are applying the chrome to. Put your hand on a car bumper in the middle of August/summer, it will be hot and vice versa in December/winter.

if anybody want chemical formula in india for chrome plz feel free to contac me

ansari send me your no

Please send me your Mai id and phone number

I bought a kit from ALSA, and it was crap, even after they told me how to do it , that were not in the instructions. 2nd time still crap. $300 gone, and they don’t care! Won’t take calls, or answer fax’s. I still have their special 2 in one spray bottles I kept for a reminder Could’nt make it work on plastic, or metal, and they can make it work on shoes.I’ve been coating, and spraying for over 50 years, so I do have some knowledge.

Surface prep is paramount. I went through a couple of cans before I figured it out. It has to be like glass and super, super clean as well as not too cold either.

There are a ton of their video’s on YouTube as well.

go here and watch this guy.

https://www.youtube.com/watch?v=WjN-vW16gmQ&ebc=ANyPxKo7d79ddnBdllWk-5WDoK85uLBPf1FJaAOjHKmu0P1ZGqVXbuxXqbTib-CliqRvqdzDCVJxitPQcBpvLxPzOKgta28-lw

I want tis prodact

Hi, I’m in the uk. can anyone tell me, would any of the chrome products on this web site work on chrome bumps. Yours Chris.

I want to learn the chRome plating on headlight reflector

I am interested if you guide me

I want to know about plating on plastic bangles pls guide me

Back in the late 50s and early 60s, model cars started coming out with chrome plastic parts and everyone wanted to know how it was done, but the kit company wasn’t willing to share that info.

How can i buy this chrome soray

The Samsung Galaxy Note-10 is among the most preferred smartphone gadgets ever with its sleek design, brilliant picture quality and a classic look. It packs one of the top-quality sound systems in the world of electronic devices.

I want to run chrome on plastic, I saw on YouTube someone doing this by spraying three substances, does anyone know what those three substances are? Please help me.

hamidsamyohe@gmail.com

ALL LINKS ARE BROKEN!!!!!!!!

Pathetic!

Consider this was written 9 years ago so… take info and links for what they are today…

Back in the late 50s and early 60s, model cars started coming out with chrome plastic parts and everyone wanted to know how it was done, but the kit company wasn’t willing to share that info.