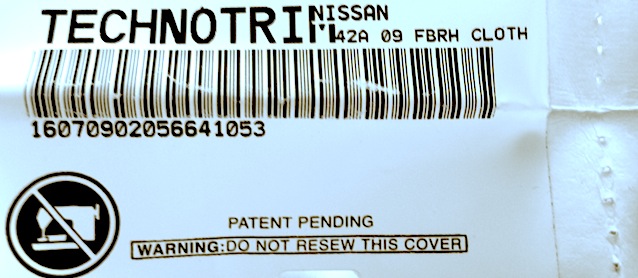

For many years, there has been confusion within the auto upholstery industry over whether it is safe or even legal for trimmers to repair seats that contain side airbags. Well Nissan has made it clear by attaching the above warning label to its seat covers.

Many automakers, like Nissan, install airbags within the driver and front-passenger seats beneath the backrest bolster facing the door. In the event of a side-impact collision, the airbag deploys – bursting the foam and splitting the unenforced French seam that holds the cover together.

While insurance companies cover the cost of new backrest seat covers, the collision repair shops that often outsource the work to local trim shops ask that we merely re-sew the open seams in order to increase their profit margins.

The problem with doing this is that we cannot guarantee that the new airbag will deploy properly if another accident occurs. Some suppliers sell “airbag thread” for such cases. But ultimately the responsibility of whether the seam opens when it needs to falls on our shoulders.

Needless to say, I’m hesitant to take on such jobs. If a seam I make doesn’t open when it’s supposed to and a driver or passenger is hurt, the ensuing lawsuit could bankrupt my family business and shut me down for good.

Well Nissan’s new warning label – which reads: “WARNING: DO NOT RESEW THIS COVER” – puts an end to the question over whether we should or shouldn’t take on such jobs.

On one hand it’s a relief to finally know the answer. On the other hand, it really stinks.

Nissan could just as easily do as some automakers and place its side airbags in its vehicles’ door panels or in plastic compartments located on the side of the seats. Doing so would provide similar protection in the event of an accident and still make it possible for auto trimmers to repair their seat covers.

But because Nissan chooses to install its side airbags inside its seats, we have to tell customers – even those with minor repairs – that they must order a whole new cover. Not surprisingly, the price of doing that often deters them from ever coming back.

With more and more automakers following Nissan’s lead, it seems that there may come a day when we’re prohibited from doing anything but installing ready-made seat covers.

Love them katzkins

I recently became aware of TheHogRing .com through DLT’s monthly newsletter. I want to thank Naseem for providing a forum that not only is informative, but also allows upholsterers/trimmers an opportunity to share our ideas and thoughts. My response today is regarding the question of sewing seat covers with airbag seams.

I have been doing interiors and more for over 37 years, owning my own business for 26 of them. When seat covers with airbag seams started being introduced; I too was hesitant to sew them. Refusing at first, then having clients sign waivers, I still had concerns for the safety factor involved. A high percentage of my business is high-end custom interiors on i.e., Mercedes, Audis, BMWs, etc., in exotic leathers, skins and suedes with unique sewing designs. There are no seat cover manufacturers that I know of that offer these options.

After asking many distributors if they offered thread to sew these covers, I was told no and they don’t plan on carrying them because of insurance concerns. I started to research thread companies and found that Coat, PLC. of England supplied the global industry with the thread to sew airbags and seat covers. After phone calls and e-mails to them, there North American representative called me and we had a lengthy conversation about thread. He informed me that what they supplied the industry with for seat cover seam airbag deployment was a bonded nylon in #45 weight. This thin of thread does not seem to be carried by most auto trim suppliers. I found boxes of bonded nylon bobbins in #69 weight.

I now sew my seat covers with heavier polyester top and bobbin thread, lock my stitches above and below the airbag area, change both of the threads to lighter #69 weight, finish sewing the seam overlapping the polyester thread, but not locking the stitch. I always felt comfortable with the safety of the covers the way I am sewing them.

I was able to test my method when I had an insurance company replace a passenger front bucket seat on a Nissan Altima. I took the old seat and cut it open and resewed the seam using my method. I then exploded the airbag and recorded it to show that the seam blew apart properly, without any problems.

I feel confident that all the airbag seams I’ve sewn will function properly. I uploaded two videos of the deployment and a close-up video of the blown seam to Youtube.com for other trimmers to see. I hope this answers some questions about this issue. Funny how the seat I happened to have tested happens to be a Nissan seat. Here are the links.

http://www.youtube.com/watch?v=Qv7vbNWPQEM&feature=plcp

http://www.youtube.com/watch?v=rTIJL56XY-E&feature=plcp

http://www.youtube.com/watch?v=aXWX0U5SAgM&feature=plcp

Thanks

Ken

Autowerks/KNS Upholstery

Ken,

I like your approach. Thoughtful, and you tested it to make sure it worked.

I have a leather seat for my wife’s 2006 Mini Cooper S where the seam has come undone over the airbag (which has NOT been deployed.) The seam is open rom the driver’s elbow up to the head rest. Can you fix it for me?

Thanks,

Richard

Hey Ken, thanks for joining The Hog Ring and for your kind words. Believe me, I wouldn’t be able to run the site if it wasn’t for my partner and brother, Nadeem.

I appreciate you describing in detail how you resew airbag seat covers and for describing which thread weights you use. I’m sure our members will get a kick out of your videos, I know I did.

Another reader turned me on to a company by the name of The Thread Exchange which offers a Size 46 thread.

http://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Store_Code=TTE&Category_Code=nylon-thread-information

What I would like to know besides all of the other questions mentioned is when the dealer is no longer required to supply this cover (say 5 years)what is a car owner to do? Most cars are paid for but have some in and out butt wear to the bolster where the airbag is located. I work at a automotive upholstery shop and we are loosing jobs every day and disapointing people by not being able to sew a seat in fear of getting sued. We know a airbag is capable of blowing out threads of any kind but if there is any malfunction it would be the upolstery shop to be blamed. When a airbag is delivered it comes shipped in a steel cage not a leather sewed bag.

Audi says the special thread used for airbag deployment is only good for ten years

Hi, try disconnecting the battery before you disconnect the plug under the seat. leave the power disconnected for the duration of your seat repair/recover.Only reconnect the the battery after you put back the seat and have reconnected the plug under the seat.

Don’t disconnect a VW battery. Then you an even more expensive radio reset at the dealer. Ive been trimming for 36 years and Im beginning to think its better to work at something else.

I felt the same way a few months ago when a Honda light went on. I guess I didn’t wait long enough.

It can be frustrating. Hang in there

I talked to the DOT in regards to a little bit of a different issue. I was told specifically if you make it a policy in you decleration or articles of corporation that using aftermarket procedure you assume no liability you are good to go.

Per DOT unless you are a manufactor you hold no liabilities to airbags, the policy is from a good attorney that proves in civil court unless they have proof they asked you will never lose.

I was more concerned about using these designer knock offs since, 3-4 major shops out here got sued and shut down.

Very informative , thanks. I am enjoying this forum.

I have replaced my car seats that had airbags. now I have no air bags in the new seats , it is legal as I did look up the ministry of transport which state that there is no legal requirement for these air bags. please note this is in the uk.

First things first ,hide the key do not turn key on during seat removal. If I am doing a repair on a seat back I don’t remove the seat unless needed remove cover and kevlar hold downs sew the kevlar back in on cover before the seam.fold one side of material back during top stitch .No problem with sensor .the warning light comes on because the passenger bottom thin plastic sensor is bad so never put your knee in the passenger seat to work

Just had to turn my first Nissan customer away. 2013 Nissan Altima, just got it a month ago with 18 miles on it… and the passenger top bucket seat seam was coming loose. He said the dealership would replace under warranty but the seat cover would not be in for a month. They told him he would have to leave his car there for a month until parts come in and they were going to give him a rental, so he came to me. I showed him the bulletin from Nissan and said my hands were tied and did not want to screw him over in case there was an accident or something to void his warrant. I told him to go back to dealership and have them order the cover and there was no reason for them to have to keep his car sitting there.

Huh.

Well, we’ve got in a seat from a Nissan.

The owner turned down just buying an approved seat cover with the special thread, so we bought Leather and made the seat custom.

The reason I’m puzzled with this discussion is that the airbag IS behind a plastic cover.

Once it bursts that cover will flap open and there’s no fabric in the way.

This of course is the sensible way to do it, but from the wear and tear this seat looks to be at least five years old.

I’ll insist on a quitclaim signature on the invoice anyway.

Just for clarity – this discussion is not about seat covers where the airbag is behind a plastic panel (i.e. the fabric is cut out to allow for the plastic cover). This is about seats where the upholstery completely covers the airbag and the seams needs to separate to allow the airbag to deploy.

In addition to the thread type, there is a lot that goes into the thread tension and the consistency of the stitch itself. Read this flyer from Alea Leather in which they explain how they sew their leather covers:

http://www.alealeather.com/pdf/Alea%20Leather_Spotlight.pdf

It will give you a general sense of what goes into factory airbag seam technology.

–Jim

Hey, thanks. Why don’t they do them all with plastic panels?

I wish they did make them all behind the plastic panels. Then we’d be able to work on all backrests with no issues.

The auto makers should strongly consider it as it would lower insurance claims on their vehicles.

Work in a shop in kc mo. We never start a vehicle that has air bags in the seat while seat is removed. Have yet to have a problem. Also we worn all of our customers that the air bag may not deploy. We also wright caution in big letters on repair ticket. Air bag may not deploy. No problems thus far!

Hi Guys

We can answer the question for you.

We are a Nissan Supplier in Africa and not only that i will explain the need for this by OEMs and yes in the down stream you will see more and more of it coming into the aftermarket for repair or replacement.

An airbag seam is not like any other seam in the vehicle.

I would advise watching the video understanding airbags by handel street on our website http://www.handelstreet.co.za

That can explain how the airbag deployment seam works.You can also view our airbag deployment videos.

The truth of it is this.

The airbag seams which are found in seats head liners door panels knee airbags dashboards side pillars etc are all governed by the cpu box.

This also works in relation to your seat belt sensor seat railing sensor seat base sensor

back rest sensor and various sensors in relation to ones weight or tension via the seat belt in the event of a collision.

How does it affect the seam?

It affects it in the following manner

In the even of a collision the sensors register the weight height and g force attributed to the driver or front passenger.

The seat belt sensors hold the occupant in place which then the cpu calculates in milliseconds the rate or speed of deployment of the airbag in relation to the velocity of the occupant be it in a side smash front smash etc.

The seam then comes into play because at various temperature fluctuations the seam will react differently.

The thread or airbag seam is sewn on an airbag sewing station or an engineered station.

The cost of this station is horrendous and as OEM and aftermarket supply working strictly with new vehicles we have to continously keep systems up to date.

Airbags in all countries are governed by laws check with you local legal representative for info on it.

Basically you are dealing with pyrotechnics and a controlled explosion.

Now the seam has to break in exact areas based on specific measurements in relation to the cover.

The threads used are two different threads.

The barcode has to be stored digitally for 10 years in relation to the barcode number build make and model should there be any defects while the vehicle is in warranty or out of the original purchasers hands.

The other point being is after investing all that money in equipment you cannot be fully compliant yet because each manufacturer has specific specifications with regards to make model and production run.

You can have a airbag machine you can sew the cover but if you dont fulfill the mandatory legal tests of airbag deployment of which the motor manufacturers have to comply with world wide then unfortunately you cannot be deemed compliant.Those tests cost

Nissan and many other OEMs have done this due to unscrupulous dealers around the world selling there products having a sub-standard leather and or fabric interiors installed with non approved suppliers whom are not airbag compliant and the end result on a new car 2 or three months after purchase is someone looses there life because the airbag did not deploy and or airbag wires are cut due to dealer not using approved installers and leather or fabric interior kits.

Consumer protection act laws have also forced companies like ourselves and Alea to take precautionary measures and to think safety at every point of the design aspect from start to finish.

To compete at the level we and Alea are at we a hand-full of companies world wide.

We are listed by continent below

Asia

DK Schweizer (headoffice malaysia)

Pecca Leather (head office malaysia)

Alea Leather (head office hong kong)

Jackspeed (head office singapore)

Dynasty International ( head office china)

Roadwire Automotive (branches)

Europe

DK Schweizer branches

Jackspeed branches

Pecca Leather branches

Alea branches

Middle East

DK schweizer branches

Alea branches

Pecca Leather branches

Jackspeed branches

Roadwire branches

North and South America

Katzkin USA Head office

Roadwire Usa Head office

Pecca Leather Branch

Alea Branch

Africa

Handel Street

Dk Schweizer

Katzkin

Pecca Leather

Roadwire

Jackspeed

Some of us have been in the business over 20 years and still ticking over.

Bigger than that are the Lear Corporations or Johnson Controls

I hope this has helped to explain it in clearer detail

Thanks Ashraf! That is a very thorough, technical explanation of the air bag deployment process. It is amazing how tightly all of the modern automobile’s operating processes are integrated. I had a customer come in with a Model A Ford and we were talking about how the driver actually had to adjust the fuel-air ratio manually and did so pretty much based on the smell of it. It’s amazing how advanced cars have become.

Unfortunately, the basic problem raised by Naseem’s article remains the same: the advent of in-seat airbags has severely restricted the car buyer’s choices for automotive upholstery services. Without expensive equipment and certification, a typical automobile upholstery shop can no longer offer its craftsmanship and creativity to a customer without risking safety and liability. Manufacturers that can afford the equipment are forcing the consumer to buy from them and killing the competition.

We small trim shops are naturally offended because many of us believe we can offer superior materials and workmanship, and many of our customers feel so too. It reflects the trend of corporate consolidation and monopolization of the marketplace. If you have enough capital and power, you simply force competition out of the market and force feed your inferior product to the consumer.

I don’t mean to imply that the fine companies you mentioned are selling inferior products, but there are always craftsman who can do better, and the consumer should be allowed to hire those services. This is the issue at hand.

–Jim

I just stumbled on this thread. If you undertake airbag get seat repair, you are setting yourself up for a huge liability. The auto manufacturers spend large sums of money researching and developing their safety systems. Do any of you seriously believe that you have the qualifications to determine the safety of a repair of this type? In some states tampering with the airbag system is illegal. Having a customer sign a waiver probably will not protect you.

Been 40 years a hard hit body shop owner .My decision is not to sew or repair any part of the airbag safety system with anything other than certified oem parts .Nearly all newer cars owners have collision insurance .I am not willing to risk my shop and property and my future as well as my families over saving the customer a grand .I can afford to refuse to repair a seat .I can not afford to chance losing everything due to a silver tongued lawyer. Ask yourself what your future is valued at.Talk to the auto manufacturers and try to get them to encase the seat bags in modular pods that are self contained .

I am rebuilding a 65 Chevelle. Until the upholstery is installed, I am installing a seat to keep my butt off the floorboard. The temporary seat I am installing is from an unidentified car (most likely foreign, but I don’t know), from a salvage yard.

Other than using electric tape to cover exposed plugs under the seat, (from accidental static), should I worry about using the seat or accidentally setting off a side airbag?

The seat has a tag along the side seam of the seat that says “SRS Airbag System”.

Thanks for advice and any info!

Signed,

No Idea

do they have classes for air bag certification? Would be great for all of us.

There is no way they can account for what will happen to a seat with airbags.

If the leather gets wet. It can draw the cover and seams up and change the trajectory of the airbag.

They are just trying to make people by-pass the guys, that are out here trying to help them look good and save there customers a-lot of money.

If you are putting the seat in a classic car that has no airbags, can the seat with airbag deployment be resewn and repaired?