Bentley Motors equips its auto trimmers with expensive machinery and tools to upholster interiors. But to wrap steering wheels, staff rely on a simple kitchen utensil to get the job done.

In an article by Automotive News, Bentley trimmer Noel Thompson explains how he uses a dinner fork to ensure stitches on steering wheels are evenly spaced:

Markings have to be made to show the worker where to hand-stitch the leather, Thompson said pulling out an aged eating utensil: “This is the world-famous fork.”

“We have gone back to the old way of doing it — we use a fork,” Thompson said as he poked the uniformly spaced marks into the leather as you would on a pie crust.

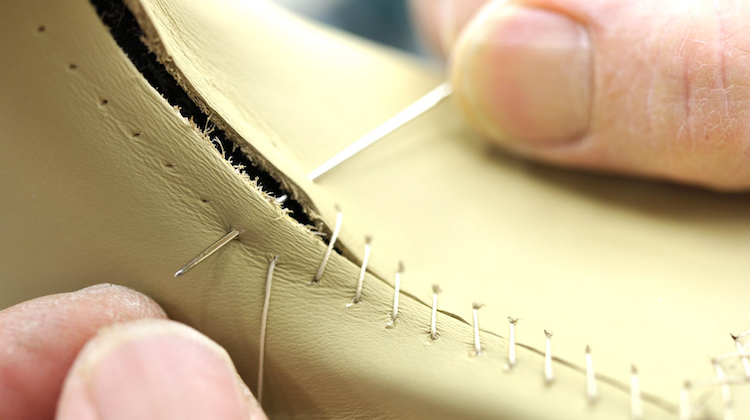

It takes two hours to sew thread around the wheel using a cross-stitch, he said. “I sew with two needles in one hand because you cross over quicker.

“I have done more of these than anyone else in the company.”

The following low-res photo illustrates how it’s done:

It’s funny how some things never change. Our auto upholstery shop has been fabricating tools out of forks, spoons and butter knives for two generations. A lot of other shops have been doing it for even longer.

But if it works, it works. So why wrap steering wheels any other way?

To read the full article, see “Lavishing leather, wood to defend ultraluxury.”

I really doubt in this day and age Bentley with the best machinery in the world would use a fork to mark the holes in steering wheels

Maybe if you send a old Bentley for restoration they might use this method….

Bentley is still Bentley when VW bought Bentley they also Bought the The Bentley / Rolls Royce Plant at Crewe Before the take over Most of the Steering Wheels weren’t even covered ! They Big Piano Black uggly things

Bentley is still Bentley when VW bought Bentley they also Bought the The Bentley / Rolls Royce Plant at Crewe Before the take over Most of the Steering Wheels weren’t even covered ! They Big Piano Black ugly things and Not Trimmed

I think it’s more of the trimmer’s personal preference. Nothing wrong with keeping a hand-made touch on the business.

I agree with Gtrimming… a factory of such magnitude using a fork to get the distances and make holes on the leather cover…my respects to the artisan…it’s only an opinion about using rudimentary methods to perform high quality products, despite the leather-wrapping procedure that remains as it is, a craft, and no machine has been invented so far to do it instead.

I agree with both of y’all. My personal opinion is it’s just quicker to fold in half and run thru your machine with no thread at desired stitch length. Evenly spaced holes every time.

Thats how I do it, I do use two needles and use a baseball stich to finish…

Bothbof the above is my method

Sorry to say guys you’re all wrong my father work for General Motors for 15 years guess what he did hand-stitched steering wheels granted a third of them were glued somewhere machine stitched but he stitched most by hand he could do a whole steering wheel in less than an hour it’s not that much sewing and if you research a little further in the internet you’ll find plenty of places to do it or go down to your local fabrication or Auto Interior place and ask them they’ll show you. Not just my opinion these are facts

I think the fork is used so it can compensate for stretch in the leather, just going around with the sewing machine could be good on stiff leather but on softer leathers there maybe some trimming needed before the holes are made.

I agree.

I personally like to use an English butter knife & bread roll, like they did in the old days for perfect results every time xxx

They would surely just use a pricking iron like the do when making saddles for horses